Core Technologies

Core Technology of KGK

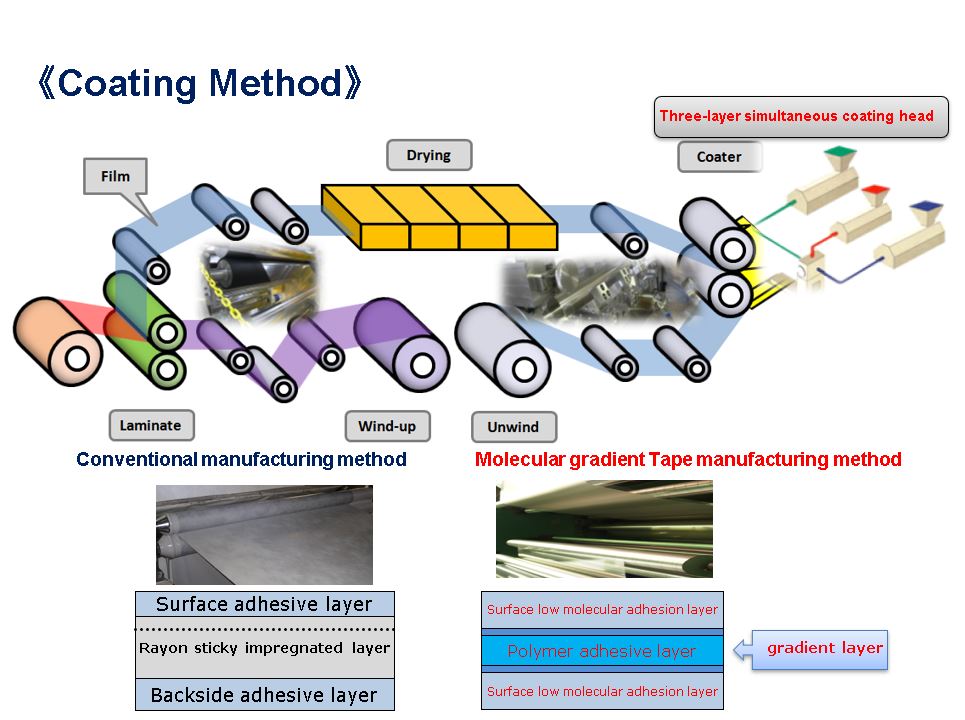

Three-layer simultaneous coating"Molecular Gradient Tape manufacturing method"

The three-layer simultaneous coating technique (molecular gradient coating technique) is a technique to increase the intermolecular attractive force and produce a strong adhesive force by gradually forming a resin solution from the center layer to the outer layer.

Using this technology, we will derive superior performance over conventional double-sided tape (nonwoven fabric, base film base material double-sided tape, etc.).

Due to this gradient layer, the molecular gradient tape is not only strong tacky but also good warp followability, shock absorption and anti-static loading. Since all of the thickness of the tape contributes to adhesion, it can demonstrate adhesion strength, heat resistance, viscoelasticity 1.5 to 2 times higher than conventional double-sided tape.

Acrylic Resin

Plastic (synthetic resin) has various kinds such as polyvinyl chloride, polyethylene, polystyrene and nylon.

Acrylic is the most used among KGK's plastics.

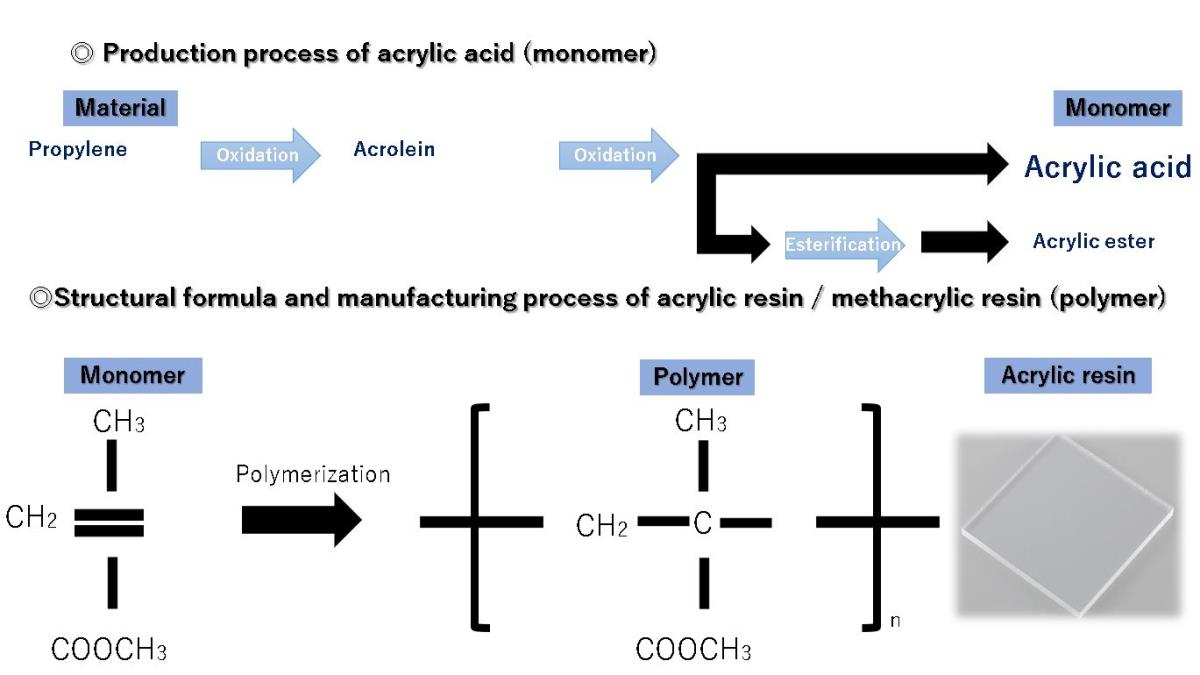

Acrylic resin is a polymer of acrylate or methacrylate.

It is amorphous synthetic resin with high transparency.Acrylic resin is hard and has excellent weather resistance.

Transparency is the highest among resins. It is tough as compared with inorganic glass, easy to process and easy to color.

Also known as organic glass. There are various kinds of acrylic (polymer of acrylate ester) as follows.

Polymer of acrylate ester

Acrylic fiber and synthetic resin Methyl acrylate

Acrylic rubber, paint, adhesive Ethylacrylate

Adhesives, adhesives, paint Butylacrylate

Adhesive, adhesive, paint 2 methylhexyl acrylate

Adhesives, adhesives, paint 2 hydroxyethyl acrylate

Highly water-absorbent polymer such as paper diaper Sodium polyacrylate

*Generally acrylic esters are synthesized by gas phase oxidation of propylene.

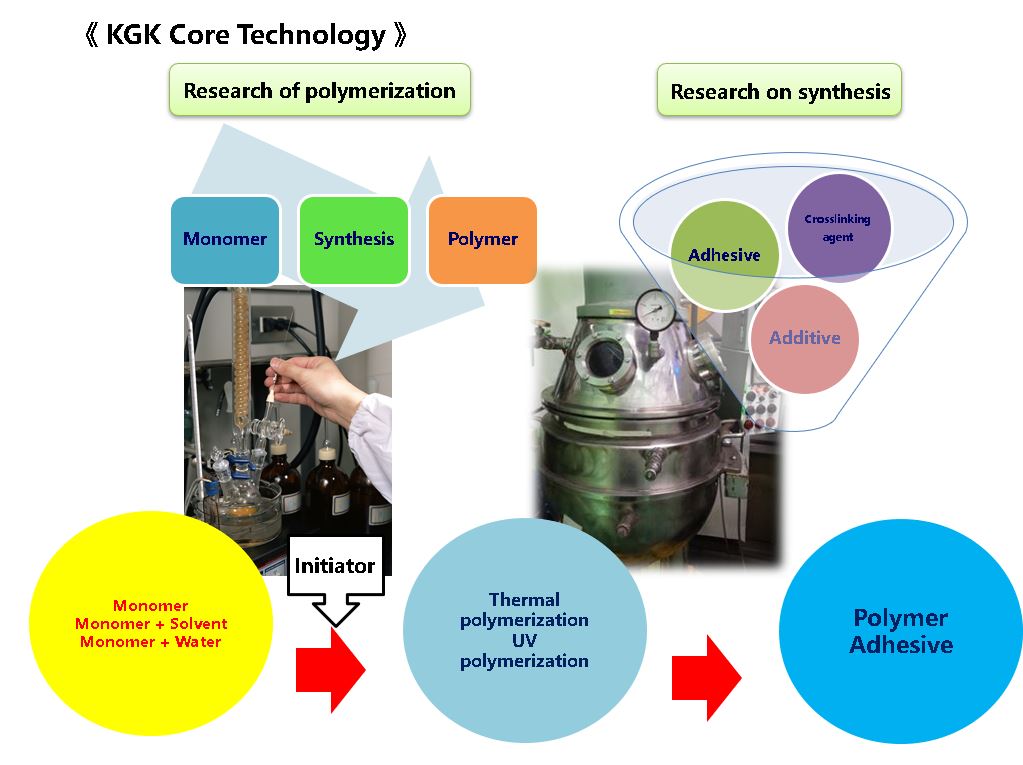

Polymerization and Synthesis of Adhesives

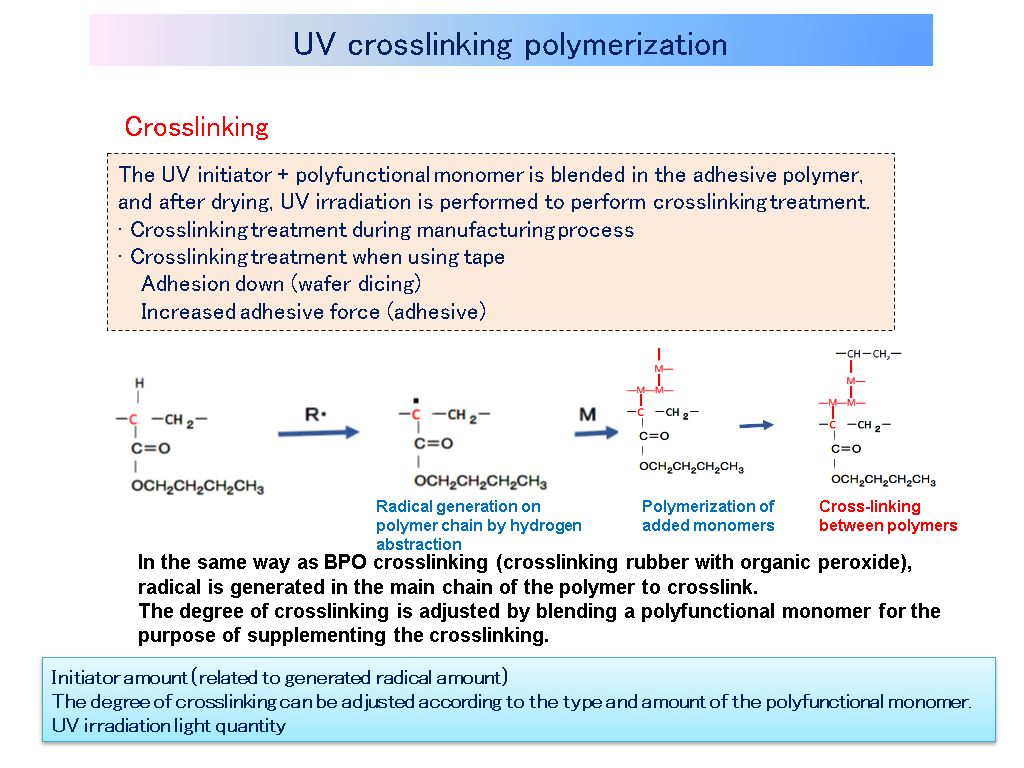

We are conducting radical polymerization of monomers with heat or UV according to customers' request.By doing so, we design the adhesive with necessary functions.

Especially acrylic adhesives are widely used for many general purpose because of wide variety of monomers and wide range of performance design possible.It is also the main ingredient in the development of current adhesives.

Acrylic adhesives are also excellent in transparency, weather resistance and heat resistance.For that reason, it is widely used for smart phones, automobiles and medical care.

Acrylic Adhesive

Industrialization of Synthetic Resin

The property as a plastic (synthetic resin) such as adhesive is manifested by plastic polymers intertwined with each other.

As a result, as long as the polymer is generally longer, the tangling becomes more complicated, so it is possible to produce high quality polymers by high crosslinking.

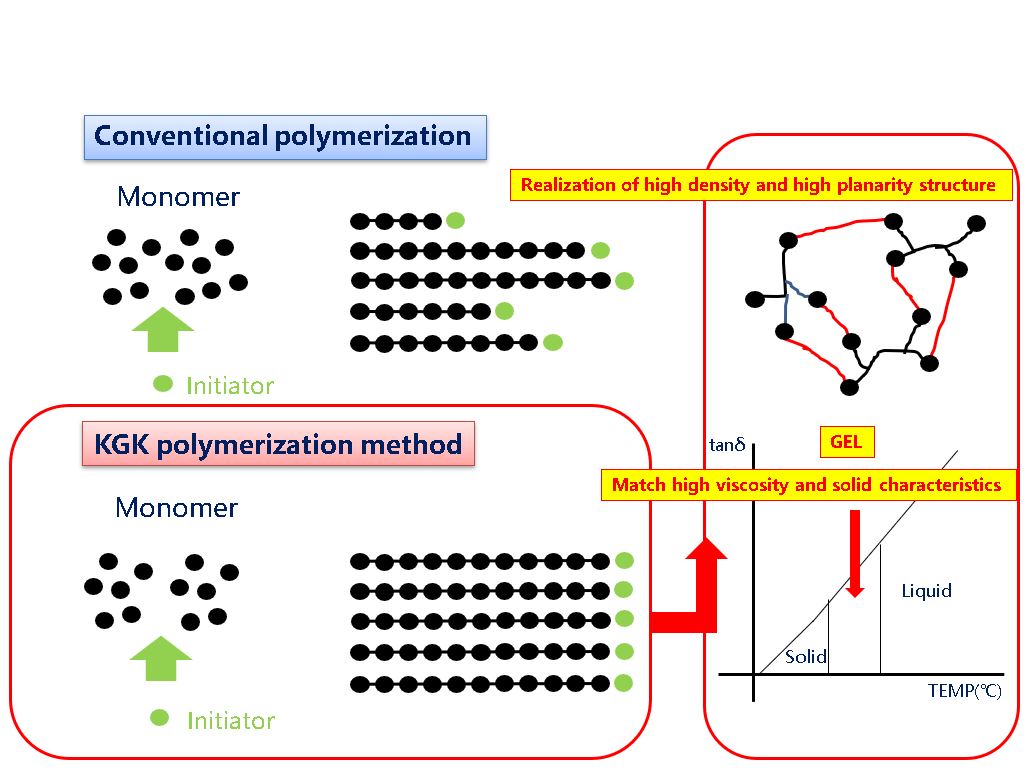

However, it is not easy to make a long polymer, so the polymerization method becomes important.

In order to lengthen the length of the polymer it is necessary to consider a polymerization method which does not contain unnecessary impurities.

For that purpose, we are researching new manufacturing methods in polymerization, synthesis and coating of acrylic adhesive products to create products with higher quality and lower cost. In caseWe can polymerize, copolymerize, synthesize, cross-link, and polymer alloy resins by using KGK manufacturing method to give high performance characteristics.

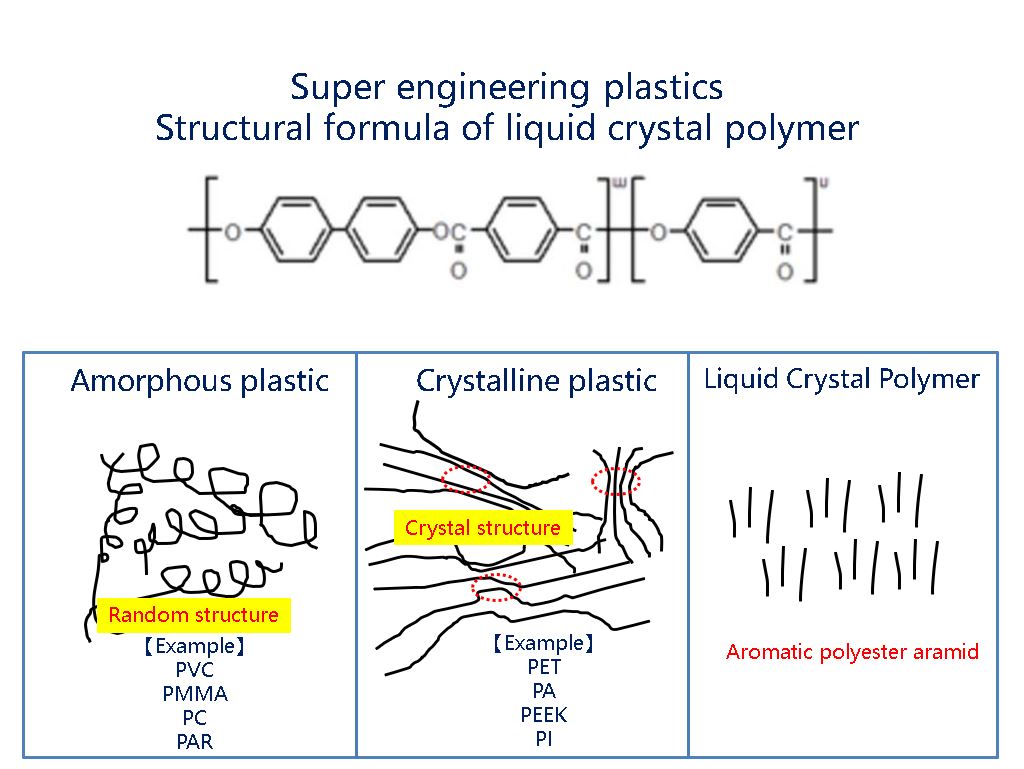

Super Engineering Plastics

No matter how high heat resistance or high strength plastics can be used for glass and metal. However, if it is a properly designed plastic it can be used without deterioration even at a surprisingly high temperature. Such highly heat-resistant plastics are called engineering plastics or super engineering plastics. KGK is studying the infinite possibilities of these plastics.A representative super engineering plastic KGK is studying is Liquid Crystal Plastic LCP.

Liquid crystalline polymer is a special aromatic polyester thermoplastic resin showing liquid crystal properties in which molecules are regularly arranged linearly in a molten state.

Orientation occurs in the molten state.

It is characterized by rigidity, heat resistance and high strength. Moreover, it is high in crystallinity and low in polarity, so it has high gas barrier properties.Super engineering plastic is also a material that is generally hard to process while it is excellent in heat resistance and strength.

KGK has succeeded in forming a film of this liquid crystal polymer (LCP) resin by using original technology. We are realizing filming for the first time in the world by the special solution cast manufacturing method we devised.

Characteristics of liquid crystal polymer film (LCP) of KGK

*Heat resistance · High strength (crystallinity).

*Gas barrier property and low dielectric / high insulation characteristics at high frequency.

*Flexibility and high strength characteristics by KGK solution casting method to eliminate the property of orientation in the molten state.

Contact

We appreciate your interest in KGK Chemical Corporation. Please contact us from the bellow and complete the requested information.

-

Business Hours Mon.-Fri. 8:30am – 5:30pm Japan time zone

- REQUEST A QUOTE